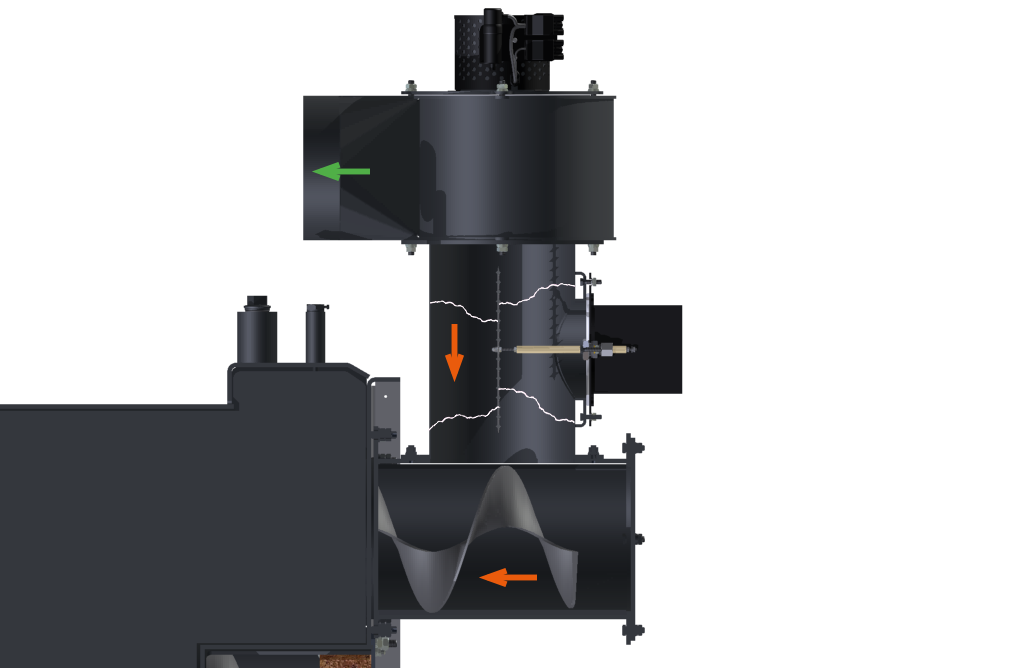

The Heizomat Extraction System

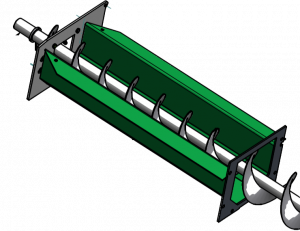

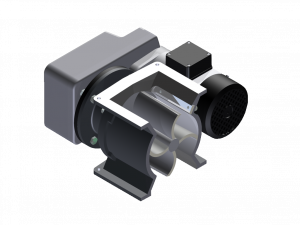

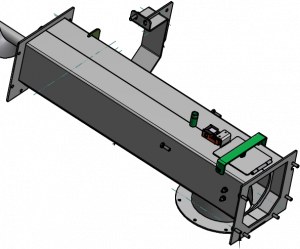

The Heizomat automatic extraction system was first designed in 1982, more than 35 years ago, to provide the convenient transportation of biomass from the fuel-store to the combustion chamber. Since then, Heizomat has technically tweaked and perfected it’s flexible in-feed system to cater to inconsistencies in fuel supply, while maintaining the highest safety standards. With the combination of high quality robust materials and an intelligent interface with the Siemens control board, the Heizomat extraction system technology is designed to last and operate with minimum maintenance. Each section of the discharging system is tailored to your individual requirements and begins in the fuel store with the automatic delivery of the fuel, feeding to your Heizomat boiler.

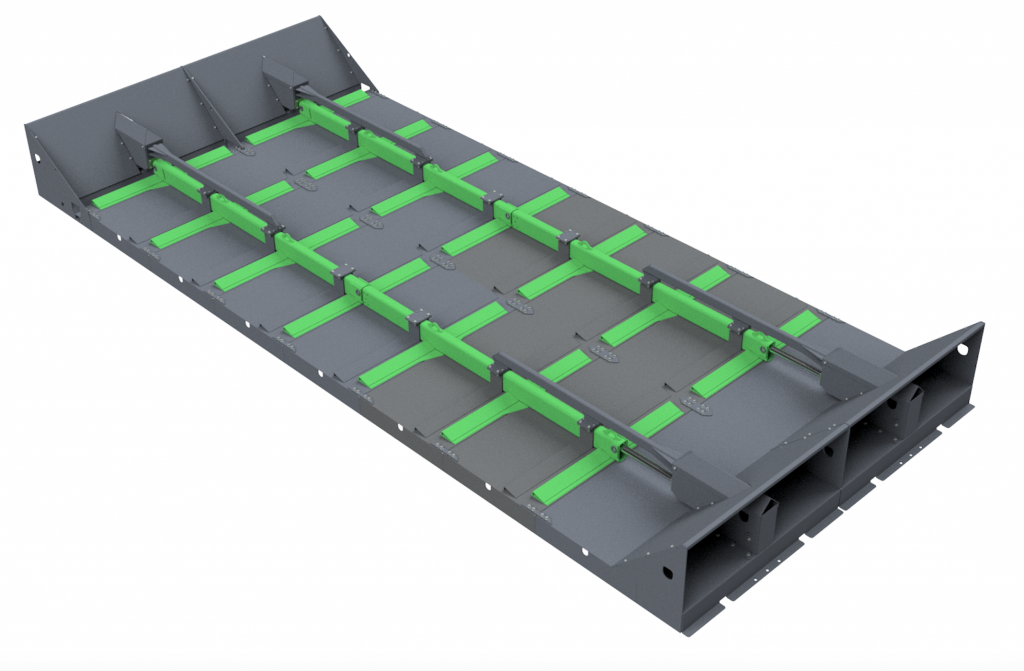

Heizomat are also proud to offer an alternative feeding option in the form of the Heizoschub push-floor.